Acoustic, Fluidic and Mechanical Metamaterials

Our research

Acoustic metamaterials

Acoustic metamaterials are composite materials, typically with small and closely placed resonant inclusions, which have been designed to control, direct, and manipulate sound.

Propagation of sound in materials is mostly dictated by the bulk modulus and mass density, which are analogies of the electromagnetic parameters, permittivity and permeability.

However, just like in the electromagnetic domain, there is a drive towards ever increased device performance and functionality, and metamaterials offer an opportunity to look beyond naturally-occurring materials since they can be engineered to have completely artificial behaviour.

Our research

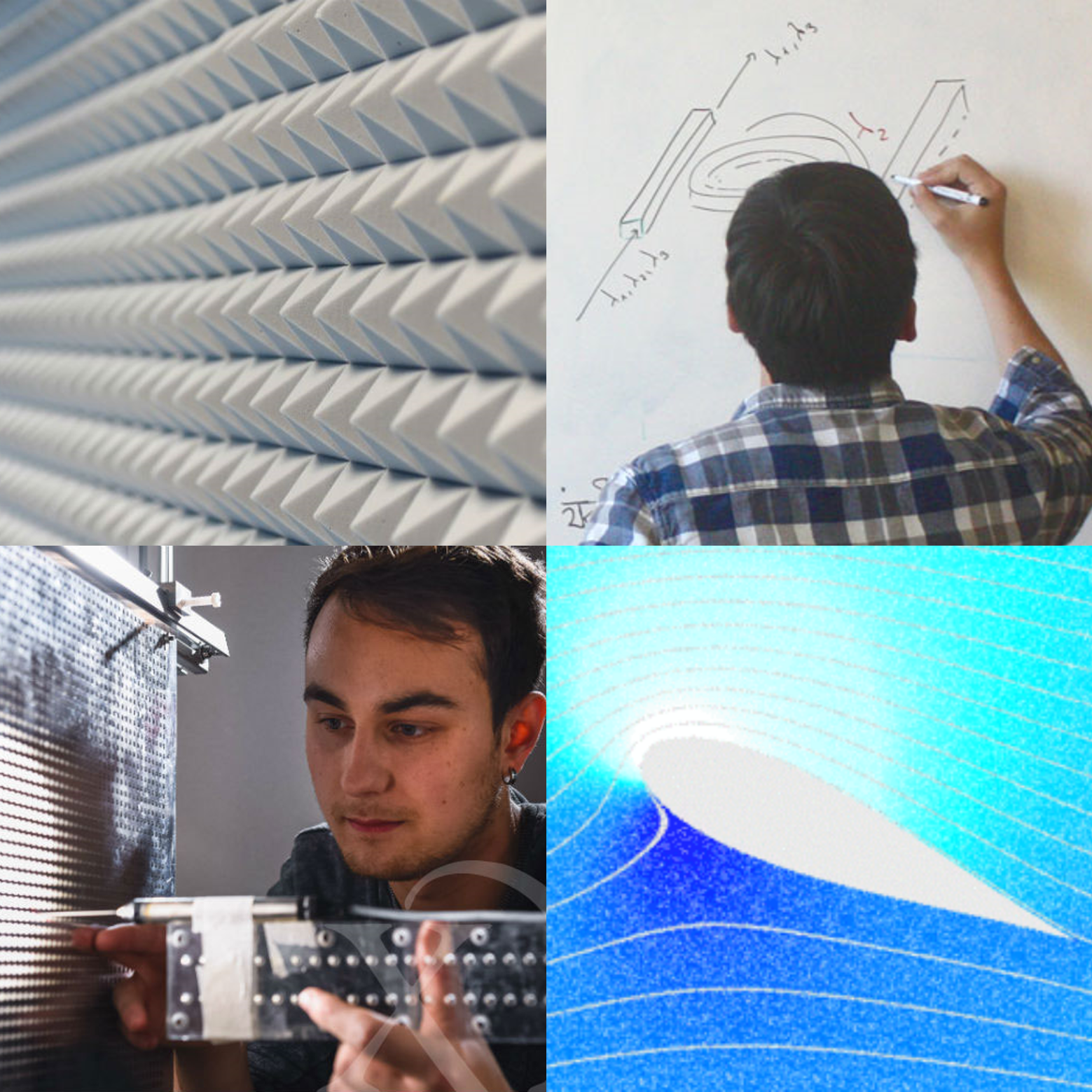

Our work in acoustics is fundamental in nature, exploring the phenomena that are revealed through adopting metamaterial concepts. It focuses on sound propagation both in air, and underwater.

We investigate:

- the acoustic absorption achieved via structuring of materials,

- the selective transmission through apertures and phononic crystal structures,

- the emission of thermally generated sound,

- the coupling of sound to mechanical vibrations and fluid flow,

- the excitation of acoustic surface waves for the channelling of sound across surfaces.

Real-world applications

Our work continues to be of great relevance to end users, particularly those interested in signature control, thin absorbers, noise control, acoustic wave forming and imaging, and energy harvesting.

Fluidic metamaterials

Linking together acoustic metamaterials with fluid flow is a natural extension for our research. For example, screening sound using a perforated metasurface that allows free-flow of air, has application to the design of windows in hot, noisy environments.

Yet there has been little work on more widely applying general metamaterial concepts to realistic fluid flow situations, despite the fact that this technology might have great potential - providing new avenues for the control of flow noise, energy harvesting, and the shielding of surface mounted instrumentation.

We have a number of ongoing projects to exploit this potential, exploring the fundamental physical mechanisms that come into play when metasurfaces, metamaterials, and driven mechanical elements are used within fluids.

These include using patterned metasurfaces or elastic resonators to reduce drag, harvest energy, or delay the onset of turbulence. We are also actively pursuing the study of magnetically actuated motors (or ‘swimmers’), and the potential of influencing microfluidics via collections of these meta-atoms.

Mechanical metamaterials

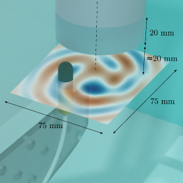

The vector system of elasticity presents additional complications when compared to scalar acoustics, as in a solid there exists two body waves (shear and compression), that co-exist and travel with different wavespeeds; these wave types are inherently coupled and therefore resist independent manipulation. Surface Rayleigh waves also exist at traction-free interfaces.

These elastic waves are present all around us in the form of vibrations, across a large range of scales ranging from small-scale surface acoustic wave devices, ubiquitous in electronic circuitry present in mobile devices, to larger scales that we feel in our immediate environment, such as noisy domestic appliances, all the way up to groundborne seismic vibrations caused by earthquakes. Elastic metamaterials offer a route to manipulate and control such vibrations over these length scales, offering applications in energy harvesting, vibration isolation and noise control.

Our research

Just as in our acoustics research, our work on elastic metamaterials is fundamental, investigating the manipulation of elastic waves through metamaterial techniques.

We investigate:

- the coupling of sound to elastic structures,

- noise control and vibration mitigation,

- elastic energy harvesting,

- phononic metamaterials for sensing and signal processing applications,

- mode conversion from surface to body waves,

- redirection and focusing phenomena,

- active mechanical metamaterials,

- time-varying mechanical material properties.

We have experimental facilities that allow for the study of sound reflection, transmission, or absorption from test panels in air and underwater, either with pulses (time-domain) or via continuous wave excitation.

We have scanning stages to map pressure fields in three-dimensional space in air and inside the water tank, and a semi-anechoic chamber for airborne measurements.

Flow tanks and particle image velocimetry apparatus are provided by our colleagues in the department of Engineering, and we are experienced users of commercial numerical modelling software (e.g. Comsol) and in-house developed analytical and semi-numerical methods.

Rapid Prototyping

- We have an Ultimaker S5 3D-printer in our labs, which we use for every-day manufacture of cm- and mm- sized photonic and phononic crystal and metamaterial designs for microwave and acoustic experimentation. It has a build volume of 330 x 240 x 300mm with layer resolution < 100 microns.

- We also have use of further college facilities in Exeter’s Centre for Additive Layer Manufacturing.

Acoustic experimentation

- A collimated beam acoustic apparatus for measuring the air-borne far-field response of test samples to high frequencies, in the frequency and time domain.

- A hydro acoustics facility to similarly characterise the response of samples underwater in the time-domain.

- Each set-up includes a computer controlled 3D scanner provides the ability for mapping local pressure fields.

- We have an semi-anechoic chamber for air-borne measurements and a 3 x 1.75 x 1.2 m (5000 litre) water tank for the hydroacoustics.

Numerical and analytical modelling

- We are advanced users of Ansoft HFSS, CST Microwave studio and Comsol Multiphysics for numerical modelling of electromagnetic and acoustic systems.

- Differential methods for predicting the response of multilayered corrugated surfaces (diffraction gratings) have been developed, together with modal matching analytical techniques for predicting the response of well-defined photonic structures.

- Our team have expertise in the development of finite difference time domain (FDTD) methods for predicting the response of advanced photonic materials, including the incorporation of the Landau-Lifshitz-Gilbert equation for the study of magnetic materials.

Our researchers in this area include:

|

|

|

| Prof Alastair Hibbins | Prof Feodor Ogrin | Prof Geoff Nash |

|

|

|

| Dr Gregory Chaplain | Prof Ken Evans | Prof Rob Hicken |

|

| |

| Dr Tim Starkey |

.jpg)