Metasurfaces making airborne communication antennas compact and lightweight

A case study by Alastair Hibbinsa and Cameron Gallaghera

aUniversity of Exeter

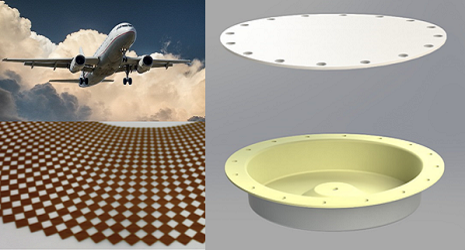

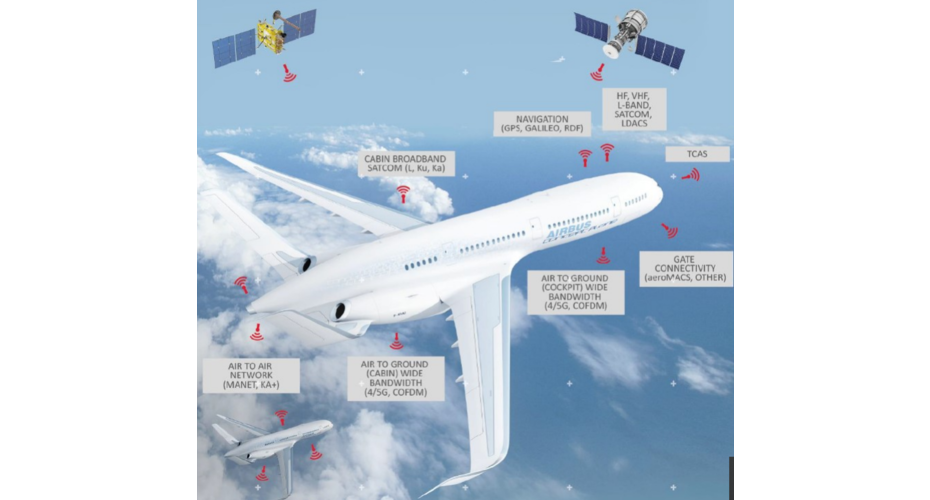

High performance, robust antenna systems are fundamental to aircraft navigation, communication and data systems – at the expense of payload, aerodynamic drag and fuel burn. We are working with our partners at Technical Composite Systems (TCS) and Cobham Aerospace Connectivity, to develop, manufacture, and quantify the performance of baseplates for airborne communication antennas. These new designs must maintain baseline operational performance (antenna efficiency and bandwidth; resilience to temperature, weather and vibration etc), but reduce size and weight.

Our solution

Conventional antenna systems employ a metallic casing (or baseplate) to reflect the communication signal, where our alternative approach replace this metallic baseplate with a lightweight, functional composite structure. Our design imparts an electromagnetic boundary condition across the operating frequency range of the antenna that maintains the antenna performance while reducing the mass and size (footprint and depth) of the required baseplate.

Why use a metamaterial?

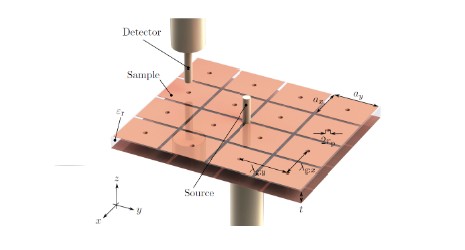

Metamaterials show great promise for bespoke antenna applications because they provide the opportunity to engineer their interaction with electromagnetic waves at the point of device design. This allows us to change the size and shape of the composite baseplate, further reducing mass, thickness and footprint. Following on from some of our work with metasurfaces, we have been undertaking research, modelling, manufacture and testing of novel metamaterials to tune our designed structure to provide the required interaction with the radiated signal from the antenna.

This project is funded by the National Aerospace Technology Exploitation Programme (NATEP).

References

- NATEP http://natep.org.uk

- TCS http://www.technicalcompositesystems.com/

- Cobham www.cobham.com/aerospace-connectivity

- Metamaterials for antenna applications, e.g. https://ieeexplore.ieee.org/document/6171815

- de Pineda JD, Mitchell-Thomas, Hibbins AP, Sambles. (2017) A broadband metasurface Luneburg lens for microwave surface waves, Applied Physics Letters, volume 111, DOI:10.1063/1.5003571, AND

- Lockyear MJ, Hibbins AP, Sambles JR. (2009) Microwave Surface-Plasmon-Like Modes on Thin Metamaterials, Phys. Rev. Lett, volume 102, article no. 073901, DOI:10.1103/PhysRevLett.102.073901