Previous Funded Projects

Investing in sustainability projects is a powerful way to drive real change—both in the lab and across the wider university community. This page celebrates the success of our previous sustainability funding, showcasing innovative projects that have made a measurable difference in our laboratories and research spaces. If you are interested in securing funding to support similar sustainability initiatives, explore the internal and external funding opportunities available on Funding Sustainable Research.

Sustainable Research Models (SRM) Fund - Round 1

In 2023, the University secured the first round of funding for the Sustainable Research Models (SRM) —an initiative dedicated to supporting on-the-ground sustainability pilot projects within research environments. This targeted funding empowers researchers and technical staff to trial innovative solutions that reduce environmental impact and improve lab efficiency. We have highlighted a selection of successful projects funded through the SRM scheme, along with the sustainability savings they achieved.

This project focused on reducing plastic waste from 3D printing by introducing equipment to recycle unwanted prints and support materials. The system grinds waste into pellets, which are then transformed back into usable 3D printer filament or plastic sheets—creating a closed-loop recycling process within the lab.

Estimated reduction of 7 kg CO₂ per year through reuse of filament spools.

This initiative established a dedicated waste stream for single-use nitrile gloves, allowing uncontaminated PPE to be repurposed or recycled rather than sent to clinical waste. By diverting gloves from incineration, the project significantly reduced both carbon emissions and hazardous waste output. You can read more about implementing this in your lab space in Waste & Recycling.

Estimated reduction of 3 tonnes CO₂ per year. Clinical waste production reduced by over 60%

This project replaced an outdated domestic fridge with a shared commercial-grade reagent fridge in a communal lab space. The upgrade not only improved energy efficiency and storage capacity but also reduced the likelihood of duplicate reagent purchases by improving visibility and access to shared resources.

Estimated cost savings of £225 per year through reduced duplicate purchases.

This project introduced a vacuum system designed to recycle coolant, significantly reducing the frequency of coolant replacement and minimizing waste disposal. By extending the life of the coolant from two months to six, the system enhances both environmental and operational efficiency in the lab.

Estimated savings: coolant waste reduced by over 50%, coolant lifespan extended from 2 months to 6 months.

Engineering Coolant Recycling Vacuum

Sustainable Research Models (SRM) Fund - Round 2

Following the success of the initial round, the SRM scheme was extended for a second round of funding, enabling even more impactful projects to take shape across our research community. Below, we highlight a selection of successful projects funded through the SRM scheme, along with the sustainability savings they achieved.

This project delivered a comprehensive upgrade to the Fish Labs’ infrastructure, including the replacement of 11 pumps, installation of energy-efficient lighting, and the addition of inverters to system pumps. These improvements significantly reduced energy consumption while maintaining optimal conditions for aquatic research.

This has led to 75% energy savings on lighting and 20% energy savings on pumps.

To improve energy efficiency in plant research, this project replaced fluorescent lighting in 10 growth cabinets with 142 energy-saving LED tubes. The upgrade not only reduced electricity use but also improved lighting quality for plant growth.

It is estimated this has has led to 68 kg CO₂ saved per year from reduced energy use.

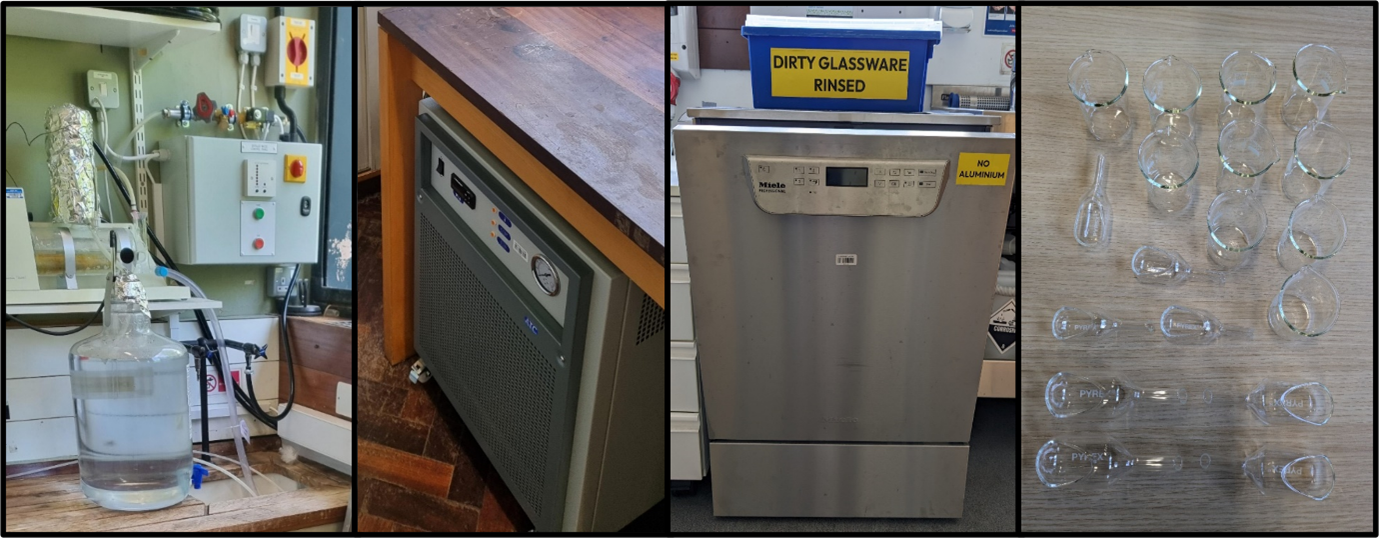

This dual initiative supported sustainable lab practices by introducing a glasswasher to encourage reusable glassware over single-use plastics, and a water re-circulator to reduce water consumption during distilled water production.

This equipment saves 23,520 litres of potable water annually, equivalent to approximately 8–11 kg CO₂ saved per year.

From left to right: Distilled water still, purchased water re-circulator, purchased glasswasher, reusable glass weighing boats & beakers.

Advancing Sustainability Initiatives (ASI) Fund - Wave 1

Following the success of the SRM scheme, the university has secured ongoing sustainability funding through profits from UniGreenScheme, which recovers value from unused lab equipment and supports the circular economy. You can learn more and get involved via our SharePoint page on sharing and redistributing equipment. Below are examples of recent ASI-funded projects, which we’ll review after 12 months of implementation.

We have replaced a variety of cold storage units across multiple research facilities with more efficient units, reducing energy consumption and overall freezer count.

Funding for equipment to start up lab plastic recycling, diverting plastic waste from clinical disposal into recycling streams.

Piloting new equipment that targets a 30–50% reduction in electricity use through improved storage and maintenance practices.

Reducing emissions associated with procurement by enabling in-house production for unique technical spaces.

Enhancing fume hood efficiency & reducing energy demand through installing more vented cabinets for additional storage needs.

Funding for a laboratory-grade dishwasher aims to use 63% less water than standard models, improving efficiency and reducing resource use.

For guidance on implementing sustainable practices in your lab, keep in touch with us with the below channels.

Keep in Touch

Contact us: sustainablelabs@exeter.ac.uk

Join our Teams channel

Bookmark our SharePoint site

Instagram: @ExeterTechs Bluesky: @exetertechs.bsky.social LinkedIn: linkedin.com/showcase/exetertechs