High performance polymers

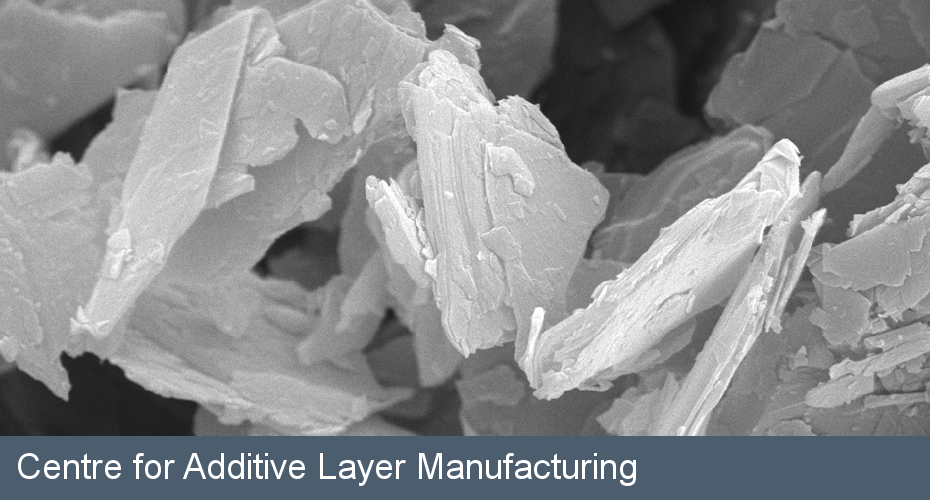

Both Exeter Advanced Technologies (X-AT) and the Centre for Additive Layer Manufacturing (CALM) have considerable expertise in the manufacture, processing and application of High performance polymers (HPPs), which have potential applications in aerospace, automotive, pharmaceutical, electronics and many other industries due to their lightweight, toughness and durability.

HPPs are defined as materials having operating temperatures, in air, higher than 150°C, with examples of these hard wearing, high performance polymers being fluoropolymers such as PTFE, modified phenolics, polyaryletherketones (PAEKs), polyimides, polyphenylenesulfide (PPS), and aromatic polysulfones (PSU).

The challenges that Exeter Technologies Group is trying to address through our research programmes are to:

- Create new materials with enhanced functionalities: chemically modified with bespoke molecular characteristics and new polymeric blends combining crystalline and amorphous HPPs

- Deliver application specific multi-property HPPs

- Identify and understand the limiting factors for HPPs

- Investigating new ways of manufacturing and recycling

Through a range of Innovate UK funded projects we have investigated the use of novel materials and developed a good understanding of how to design moulds and control processing conditions when using HPPs and manufacturing thick sections (e.g. up to 60mm). Read more.

Being the only independent centre worldwide researching laser sintering (LS) of high temperature polymers using the EOS P800 system and EOS P810, CALM has developed an in-depth knowledge of high performance polymers including PAEK materials (PEEK/PEKK etc), and has used this for optimisation of materials for both LS and material extrusion. Read more.

We use traditional and novel techniques to develop the next generation of composite materials for AM that offer multifunctional capabilities, such as working with MOFs, Graphene and Boron Nitride for various adsorbancy, conductivity and insulating properties, whilst developing a deep understanding of the crystallisation kinetics of the materials Read more.